Our Story

Who We Are

Pushpa Exports, a Pushpa group of companies welcomes you to the realm of handicrafts era. The group is engaged in the array of artistic workmanship since 1970’s. The group is involved in Manufacturing & Exporting of Silver, White Metal (German silver), Meenakari – Enamelled, Wooden, Bone-Seap Inlay, Marble and Metal articles & Furnitures, Paintings & Textiles and is domiciled in Udaipur – The city of lakes, India.

Pushpa provides a mesmerizing collection of Hand Crafted furniture & Marble Artifacts under one roof. Contemporary, Classical, Colonial & Rustic Designs of Pushpa are replicas to the one which were once adorned by the beautiful palaces all over the world.

Backed by a highly skilled team of artisans, craftsmen & designers, ‘Pushpa’ is committed to deliver the best to the customers.

Pushpa has a broad product portfolio of more than 3500 products Which truly matches with the taste of royal dynasties of the world, be it Moughal, Roman, British or Rajput Dynasty Commitment to quality, unique designs and customization has won the group accolades in the international arena.

What We Believe

We make hand crafted products only. We do not use automatic machines to make these products. As we believe that it not only strengthens our Indian culture and tradition but also provides a unique touch to every product. Hand carving takes time but the carved products made using automatic machines look more like made out of plastic moulds. Hand carving is done keeping in mind the taste of the client which is not possible in case of automatic machines. Human touch multiplies the beauty of every product by many folds.

Be it Ferrari, Bentley or Rolls Royce, they are the one of the biggest luxury car manufacturers in the world. They have huge plants and infrastructure, but still even today, their cars are handmade. They can afford using automatic machines to make their cars but still they prefer human made cars because they know that in the end the human touch will make each car a special one. And that is why their cars are the costliest and most admired in the world. And that goes for every hand made product.

Our Factory

Pushpa Exports owns 7 different factories. Each dedicated for a special kind of work. We have a Wooden Work Factory, White Metal & Brass Work Factory, Silver Work Factory, Marble & Stone Work Factory, Bone & MOP Work Factory, Semi Precious Stone Work Factory and Glass Inlay Work Factory. Each factory is equipped with high skilled artisans and with all the required tools.

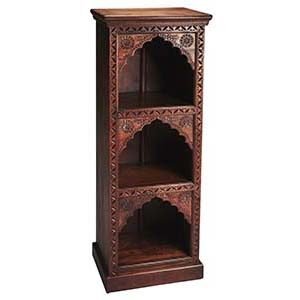

Wood Work Factory

In Pushpa Exports’s wood factory all kinds of wooden work is done. Wooden structures of all kinds of plain and carving furniture are made here. Be it white metal furniture or silver furniture or bone furniture or MOP furniture, plain wooden furniture structures for all of them are made here. For carving furniture, hand carving on wood is also done here. The carvings are made by highly skilled artists. They do all the drawings on paper first and then they paste these drawings on the wooden structure. Then these wooden structures are carved exactly according to the drawings. All carving work is done by hand. Here all furniture items like Almira, Chest of Drawers, Beds, Boxes, Candle Stand, Dressing Table, TV Cabinet, Lamp, Chandelier, Chairs, Chess Table, Coasters, Dining Table, Computer tables, Doors, Jharokha, Frames, Mirrors, Lounger, Settee, Diwan, Palki, Rath, Mandap, Counter, Sofa Set, Couch, Statues, Stool, Chowki, Swing, Jhulla, Table, Temple, Trolley, Wall Panel and many other products are made.

After making all these wooden structures, each product is then sent to its respective factory for further finishing work.

White Metal & Brass Work Factory

In Pushpa Exports’s white metal and brass factory all kinds of wooden carved and plain structures are brought from Pushpa Exports’ Wooden work factory. Wooden structures of all kinds of plain and carving furniture are then covered with white metal sheet and brass sheet. This depends on client’s choice. If the client wants a silver look for the handcrafted furniture products then we use white metal sheet. And if the client wants a golden look for the handcrafted furniture products then we use brass metal sheet. Depending upon customer’s choice, some products are completely covered with white metal sheet and brass sheet and some products are partially covered with white metal and brass sheet. For partially metal sheet covered products, the remaining wooden area is then polished with different kind of wood polishes. Many clients also ask for a combination of white metal sheet and brass sheet to be used on the furniture. In local language we call it “Ganga-Jamuna”.

Firstly the wooden area is sanded very finely and then the white metal sheet and brass metal sheet is pasted on the wooden structure using best quality adhesives available in the market. It is a very tedious job to insert metal sheet in all areas as most of the products are heavily carved with beautiful designs. So it requires experienced artists only. After pasting the metal sheet on the wooden structure, the artist makes beautiful drawing on the metal sheet with hand tools. These drawings give the final look to the complete structure and make them look royal and elegant. Locally, this drawing work on metal sheet is called “Contri Work”. After that if the product is completely covered with white metal sheet or brass sheet or a mixture of both then it is treated with chemical to maintain its shine and color for a long time. And if the product is partially covered with white metal sheet or brass sheet then the remaining areas are sanded again and then those areas are wood polished.

Silver Work Factory

In Pushpa Exports’s silver work factory all kinds of wooden carved and plain structures are brought from Pushpa Exports’ Wooden work factory. Wooden structures of all kinds of plain and carving furniture are then covered with Pure Silver metal sheet. Depending upon customer’s choice, some products are completely covered with silver metal sheet and some products are partially covered with white metal and brass sheet. For partially silver sheet coated products, the remaining wooden area is then polished with different kind of wood polishes. Some clients want a combination of silver sheet and brass sheet on the furniture. In local language we call it “Ganga-Jamuna”.

Firstly the wooden area is sanded very finely and then the Silver sheet is heated with a burner till it softens a bit. Then best quality adhesives are applied on the wooden structure and silver sheet separately. They are allowed to dry for some time. And then the silver sheet is pasted on the wooden structure. Heating the silver sheet to a fixed temperature softens the silver sheet which helps in pasting the silver in even most intricate kind of carvings. And the bond of wood and silver sheet is also strengthened. It is a very tedious job to insert silver sheet in all areas as most of the products are heavily carved with beautiful designs. So it requires experienced artists only. After pasting the silver sheet on the wooden structure, the artist makes beautiful drawings on the silver sheet with hand tools. These drawings give the final look to the complete structure and make them look royal and elegant. Locally, this drawing work on metal sheet is called “Contri Work”. After that if the product is completely covered with silver sheet then it is treated with special chemical to maintain its shine and color for a long time. And if the product is partially covered with silver sheet then the remaining areas are sanded again and then those areas are wood polished. And then the complete structure is coated with chemical coating.

Marble & Stone Work Factory

In Pushpa Exports’s Marble and Stone Factory, all kinds of stone and marble work is done. Different kind of Marble and Stone are brought from the mines, according to client’s requirement. Different products are made from these stones like temples, god idols, modern art, animal figures, balls, bar counter, baradari, gazebos, bathtubs, beds, bird baths, chess, fireplaces, fountains, pillars, god statues, inlay work, jali work, wall panels. name plates, planters, urlis, bowls, sofa set, dining tables, statues, tulsi pots and many more things. Firstly the drawings are made according to client’s design selection. These drawings are pasted on top of the marble pieces and then artisans carve the stone using hand tools according to the drawing. All carving work is done by hand. This is a very time consuming process and requires expertise. Highly skilled labor is required for doing the carving. When the carving work is completed then all the carved areas are polished using small rough stones. It is kind of sanding process which is done by sandpaper in case of wood and in case of marble and stone, it is done by rough stone. It is the most time taking process in making a stone product. It is very slow process. The labor has to rub each and every part of the product many times for many days then only the mirror finish appears. And in the end we get a complete finished product.

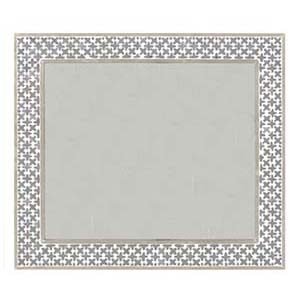

Bone & MOP Work Factory

In Pushpa Exports’s bone and MOP factory different kinds of wooden products are brought from Pushpa Exports’s wooden work factory. Wooden structures of different furniture products are covered with Bone and MOP work. Firstly, drawing are made on paper according to client’s requirement. Then the bone and MOP pieces are carved according to the drawings. These pieces of bone and MOP are used in making 2 different types of furniture. One is inlay work and the second is overlay work.

In inlay work, the drawings are pasted on wood and then wooden is dug according to the drawing. The wood is dug upto 3-4 mm deep. Then in these areas the similarly carved pieces of bone and MOP are inserted and are fixed using good quality adhesives. Then the complete area is polished so that the level of Bone/MOP and wood is same. And then the wooden is sanded finely and finally it is polished to get a nice wood polished finish.

However, in overlay work, the drawings are pasted on wood and then the pieces of bone and MOP carved according to the drawing are pasted on top of the wooden part using good quality adhesives. The rest area is then covered with plaster of paris which made in different colors, according to client’s selection. After that the complete area is polished so that the level of Bone/MOP and POP is same. In overlay, the wooden part is not visible. It is either completely covered with Bone/MOP work or with Bone/MOP and plaster of paris.

Semi Precious Stone Work Factory

In Pushpa Exports’s semi precious stone factory stones like Agate, Quartz, Amber, Amethyst, Aventurine, Crysophase, Green Margus, Jade, Hematite, Jasper, Labradorite, Lapis Lazuli, Melachite, Mookite, Onyx, Opal, Petrified Wood, Pyrite, Red Akik, Red Carnelian, Septaria, Sodalight, Tiger Eye, Webernite are used to make slabs. Big irregular pieces of stones are brought from the mines. These stones are cleaned and are sliced in different thickness according to client’s requirement. After slicing, these stones are placed together on the ground in such a way that they form a slab and then chemical is poured on to the stones. This very high quality, expensive chemical and dangerous chemical. Even a small mistake could be very harmful. When this chemical is poured it gets very hot and within a few minutes it dries and becomes solid, as strong as stone. It gains 80% of its strength in first 5-10 minutes. So, if somebody carelessly handles this chemical then he/she could be in danger. However it gains its maximum strength in 24 hours. After that the slab is then polished using marble polisher to give it shiny mirror finish. These slabs are then used as table tops, wall panels, shower panels, flooring, discotheques and many other places. These stones are also used for making different products like sinks, bathtubs, commodes, counters, frames. stairs, fireplaces. partitions and many other big and small products. The main specialty of these stones is that most of them are translucent i.e. they allow light to pass through them. So, when they are backlit using any light then they glow and that is their USP.

Glass Inlay Work Factory

In Pushpa Exports’s glass inlay work factory, wooden structures of products on which glass work is to be done is brought from Pushpa Exports’s wood work factory. Glass work is done on all kinds of wooden furniture. Firstly, drawings are made according to the taste of the client. Small pieces of plain and colorful glass are cut into shapes, as per the drawings. Then the drawings are pasted on wooden panels or wall or ceilings, wherever the work has to be done. Then the customized cut pieces of glass are pasted on the drawing according to the design. This requires experienced people only because cuts and bruises might occur while handling the sharp glass pieces. So this work has be done very carefully. When the complete glass has been pasted according to the drawing then the empty area is filled with plaster of paris paste. When the paste dries, the extra POP paste is sanded to give it a uniform level.